CATHAY equipment regards quality as life,regards users as God,and always ad- heres to the quality policy of being responsible forevery process,every product,and every user,wholeheartedly serving users.The reliable and stable quality has led to the company's sales ranking among the top in the industry,with tens of thousands of users spread across the country and exported to more than 100 countries.

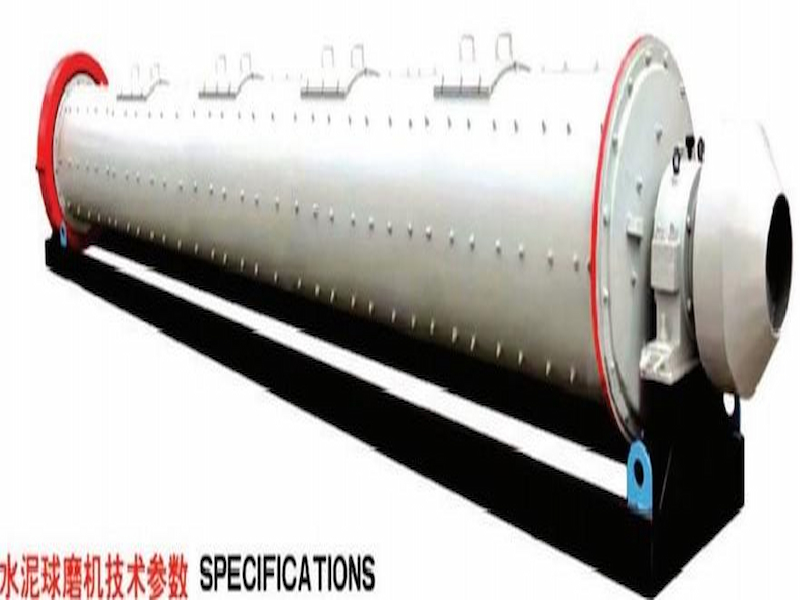

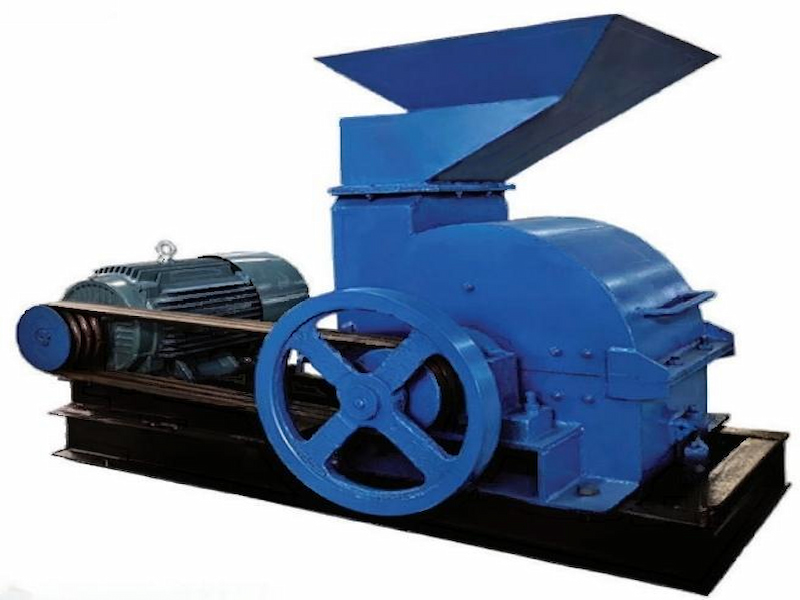

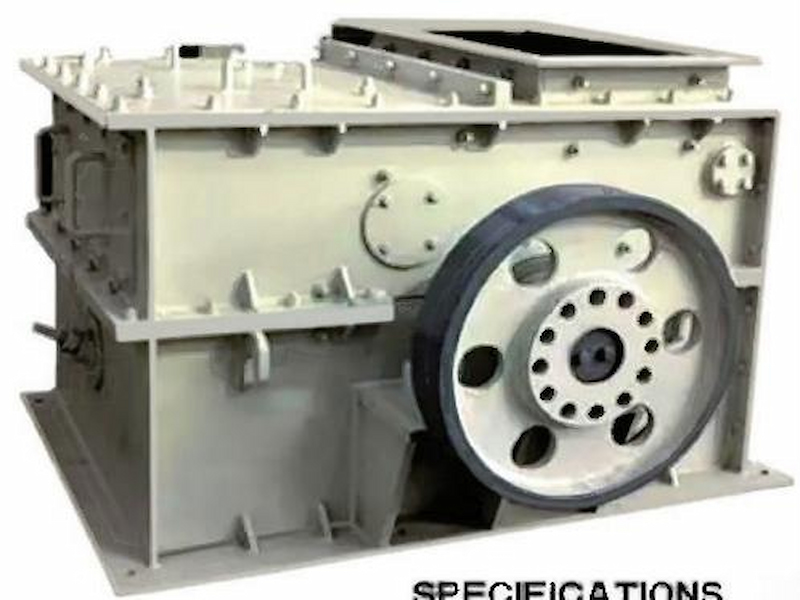

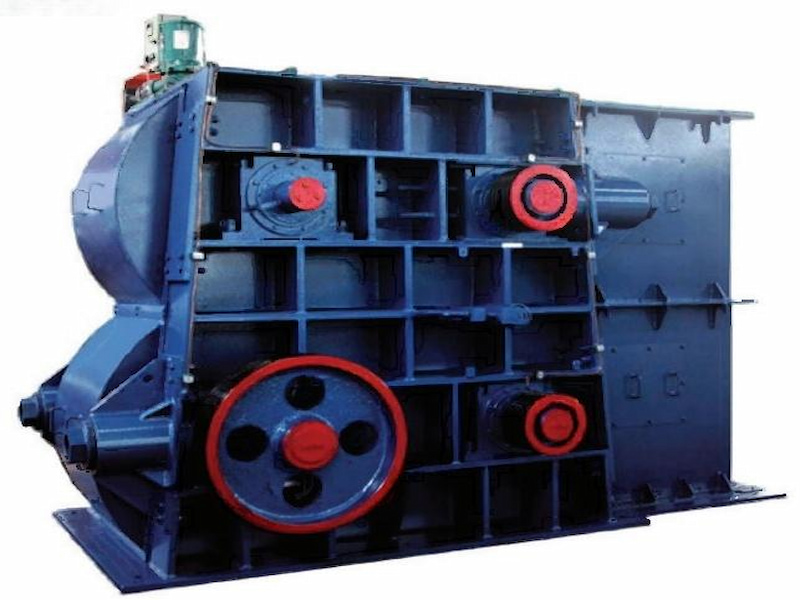

The company mainly produces feeding equipment,crushing equipment,grinding equipment,grading equipment,screening equipment,mixingequipment,beneficia- tion equipment,gravity separation equipment,ore washing equipment,flotation equipment,magnetic separation equipment,pressure filtration equipment,drying equipment,conveying equipment,slurry pumps,experimental equipment and other auxiliary equipment.In addition,the company can process and customize var- ious types of beneficiation machinery and equipment according to customer re- quirements.At the sametime,the company can provide project design,process flow design,standard and non-standard product equipment and production for users.

The equipment produced by the company is mainly used for sorting gold,silver, copper,iron,tungsten,lead,cobalt,tin,molybdenum,nickel,antimony,molybde-num,niobium,manganese ore,coal,monazite,rutile,other rare metals and non-fer- rous,black,precious metal minerals,etc.