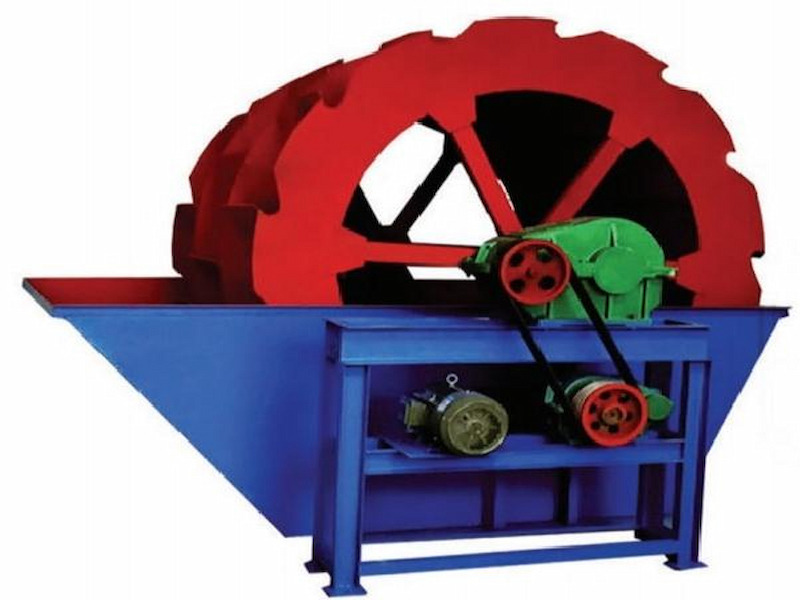

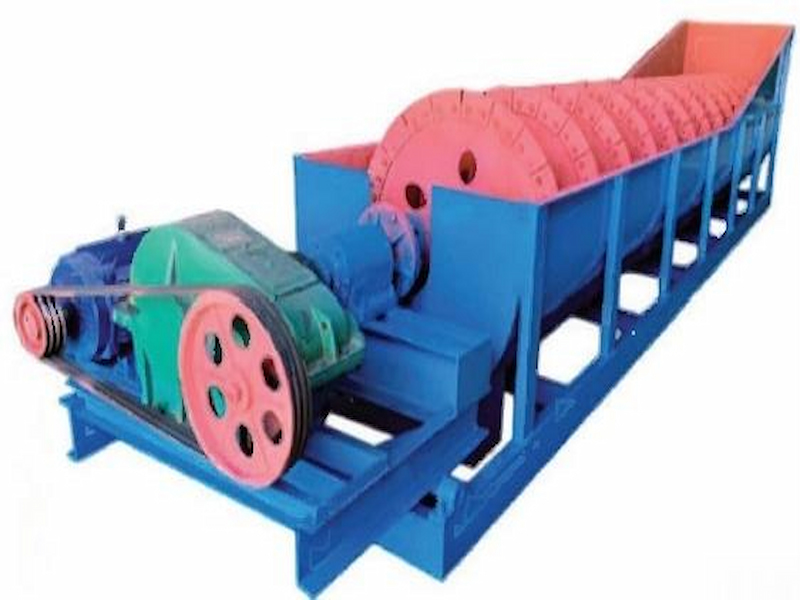

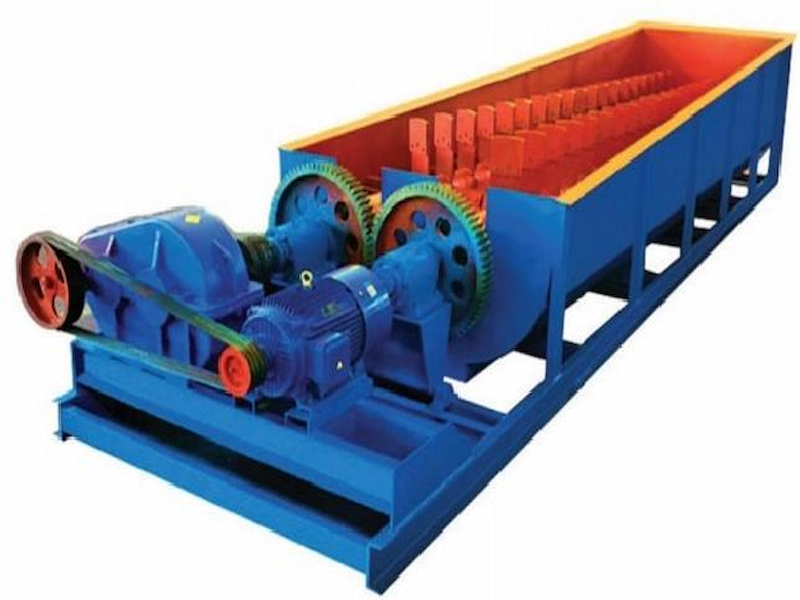

Product Overview

CATHAY sand washing and dehydration machine integrates three functions: washing + dehydration + fine sand recovery. A single machine completes the process of three traditional equipment. The washing rate is ≥99%, the moisture content of finished sand is ≤15%, the fine sand recovery rate is ≥95%, the processing capacity is 50-500 tons/hour, the land occupation is reduced by 60%, and the investment cost is reduced by 45%.

Core advantages

✅ Three effects in one

- Spiral powerful sand washing + high-frequency dewatering screen + cyclone recovery system

- Eliminate sedimentation tank, zero sewage discharge meets standards

✅ High quality control of sand materials

- Mud content ≤0.8% (national standard ≤3%)

- Fineness modulus 2.3-3.0 adjustable

✅ Energy saving and durability

- Water consumption per ton of sand 1.5m³ (traditional line 3-5m³)

- Blade lining NM450 wear-resistant steel, life ≥18 months

✅ Intelligent operation and maintenance

- PLC one-button start and stop + mobile phone remote monitoring

- Overload automatic protection

Technical parameters (WDS-200 standard type)

| Module | Parameters |

| Sand washing capacity | 200t/h |

| Dewatering screen | 1800×4500mm |

| Fine sand recovery | Recovery rate ≥95% |

| Total power | 45kW |

| Moisture content | ≤15% |

| Machine weight | 12.8t |

Comparison with traditional production lines

| Indicators | CATHAY integrated machine | Traditional three-unit machine |

| Area | 120㎡ | 500㎡ |

| Installed power | 110kW | 180kW |

| Operators | 1 person | 4 people |

| Investment cost | ↓45% | - |

Five major application scenarios

✔ Sand and gravel aggregate plant: integrated machine-made sand washing and dehydration

✔ River sand mining: ship-mounted mobile operation (rust-proof version)

✔ Mine tailings: fine particle resource recovery

✔ Construction waste: recycled aggregate washing and purification

✔ High-standard concrete: fine sand production line (including stone powder control)

Table parameters

Table parameters

|

型号 Model

|

叶轮直径(mm)

Diameter

|

筛板规格(mm) Sieve plate

|

处理水量(m³/h) Capacity

|

出砂量(t/h) 总功率(kw) Capacity Power

|

重量(kg) Weight

|

外形尺寸(mm)

Overall dimension

|

|

XS26-1224

|

2600

|

1200×2400

|

80-120

|

30-50

|

28.4

|

4935

|

5800×5200×2750

|

|

ys26-1530

|

2600

|

1500×3000

|

100-140

|

40-60

|

33.5

|

5392

|

5800×5560×2750

|

|

XS30-1530

|

3000

|

1500×3000

|

100-140

|

50-80

|

39

|

7328

|

6700×5560×3100

|

|

XS30-1836

|

3000

|

1800×3600

|

160-240

|

60-100

|

63

|

9761

|

7331×5560×3370

|

|

XS30-1842

|

3000

|

1800×4200

|

240-360

|

80-120

|

82

|

10565

|

7950×5560×3370

|

|

XS36-1848

|

3600

|

1800×4800

|

200-280

|

100-160

|

74

|

14630

|

9190×5560×4100

|

|

XS36-2442

|

3600

|

2400×4200

|

200-280

|

120-180

|

81

|

15120

|

8680×6450×4100

|

|

XS36-2448

|

3600

|

2400×4800

|

240-360

|

150-200

|

97

|

15480

|

9280×6450×4100

|