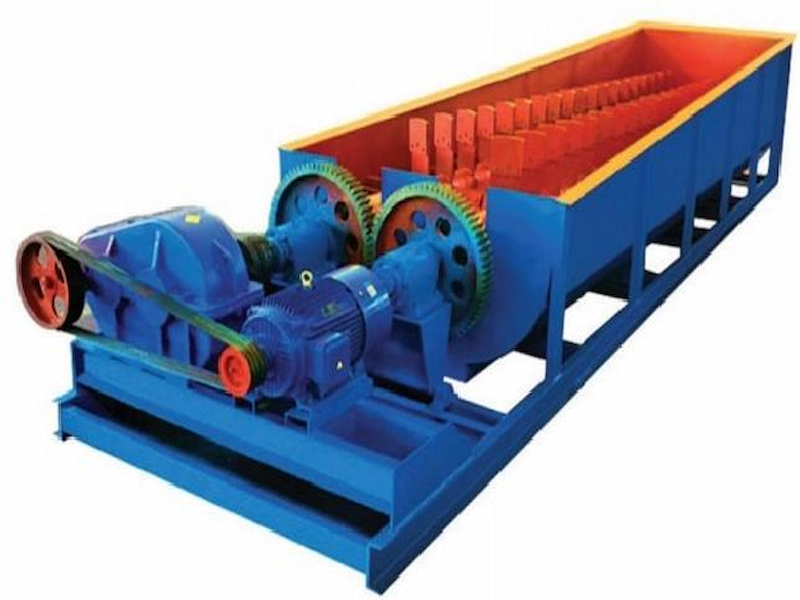

CATHAY stirring scrubber is specially designed for high clay-encapsulated minerals. It adopts dual-axis differential tearing technology to strongly peel clay from the surface of minerals. The clay peeling rate is ≥95%, the processing capacity is 50-500 tons/hour, and the mineral dissociation degree is increased by 40%, solving the problem of low recovery rate of cemented ore dressing.

Core advantages

✅ Powerful dissociation

- Dual-axis reverse rotation (25/40rpm differential speed), cemented ore group crushing rate ≥98%

- Clay residue on mineral surface ≤3% (traditional equipment ≤15%)

✅ Super wear resistance

- Blade lining tungsten carbide alloy (hardness HRA92) or rubber ceramic composite plate

- Continuous operation life ≥20,000 hours

✅ Intelligent control

- Frequency conversion speed regulation (10-40rpm stepless adjustment)

- Real-time monitoring of slurry concentration (30-70% adaptive)

✅ Energy saving and water saving

- Power consumption per ton of ore ≤1.2kW·h (traditional equipment 2.0kW·h)

- Water consumption reduced by 40% (closed-circuit water circulation system)

Technical parameters (standard AS-3000)

| Parameters | Indicators |

| Tank size | Φ3000×4500mm |

| Processing capacity | 120-200t/h |

| Power | 2×55kW |

| Maximum feed size | ≤25mm |

| Clay stripping rate | ≥95% |

| Applicable slurry concentration | 30%-70% |

Table parameters

|

型号 Model

|

叶轮直径(mm)

Diameter

|

容积(m³) Volume

|

进料粒度(mm)

Size

|

处理量(t/h) Capacity

|

功率(KW)

Power

|

重量(Kg) Weight

|

外形尺寸(mm)

Dimension

|

|

CX0.25-1

|

240

|

0.25

|

≤10

|

2-10

|

3

|

350

|

710×708×1310

|

|

CX0.25-2

|

240×2

|

0.25×2

|

≤10

|

2-10

|

3×2

|

660

|

1365×708×1310

|

|

Cx0.5-1

|

320

|

0.5

|

≤10

|

5-20

|

5.5

|

450

|

922×886×1550

|

|

CX0.5-2

|

320×2

|

0.5×2

|

≤10

|

5-20

|

5.5×2

|

890

|

1761×886×1550

|

|

CX1-1

|

480

|

1

|

≤10

|

10-40

|

15

|

1400

|

1180×1142×2057

|

|

CX1-2

|

480×2

|

1×2

|

≤10

|

10-40

|

15×2

|

2410

|

2276×1142×2057

|

|

CX2-1

|

520

|

2

|

≤10

|

20-70

|

30

|

3300

|

1597×1597×2775

|

|

CX2-2

|

520×2

|

2×2

|

≤10

|

20-70

|

30×2

|

6210

|

3075×1597×2775

|

|

CX4-1

|

770

|

4

|

≤10

|

40-100

|

55

|

7500

|

1900×1752×3470

|

|

CX4-2

|

770×2

|

4×2

|

≤10

|

40-100

|

55×2

|

14560

|

3712×1752×3470

|