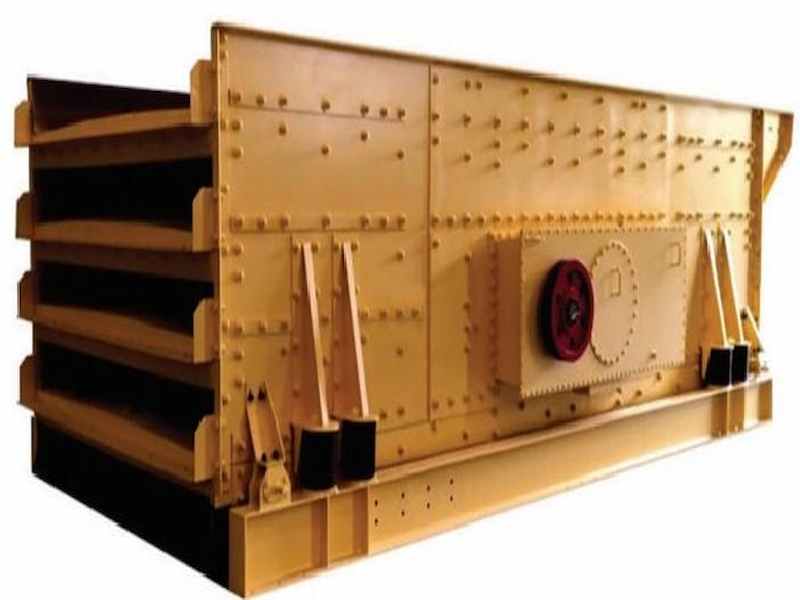

CATHAY Vibrating Screen - Professional Mineral Screening Equipment for Mining & Aggregates

Product Overview

CATHAY vibrating screens are heavy-duty screening machines designed for efficient material classification in mining, quarrying, and aggregate processing. Our screens deliver high-capacity separation with precision grading for materials ranging from coarse aggregates to fine powders.

Key Applications:

✔ Ore classification in mineral processing plants

✔ Aggregate sizing in quarry operations

✔ Coal preparation in energy sector

✔ Recycling material separation

✔ Chemical and food industry powder screening

Technical Highlights

1. Advanced Screening Technology

- Dual-Vibration System: Combined circular and linear motion for 20% higher efficiency

- Modular Screen Decks: Quick-change panels (replace in <30 minutes)

- Precision Grading: Achieve up to 5 fractions separation in single operation

2. Robust Construction

- Frame: Heavy-duty steel with anti-corrosion coating(120μm thickness)

- Deck: High-tensile woven wire/PU/rubber screen media options

- Bearings: SKF/FAG super heavy-duty series (L10 life >50,000 hours)

3. Smart Operation Features

- Variable Frequency Drive: 0-25mm amplitude adjustment (±0.5mm precision)

- Remote Monitoring: Real-time vibration analysis via IoT sensors

- Automatic Tensioning: Maintain optimal screen mesh tension

Performance Specifications

| Parameter | Specification Range |

| Screen Size | 1m×3m to 3m×9m |

| Capacity | Up to 1500 tph |

| Max Feed Size | 400mm |

| Deck Layers | 1-5 layers |

| Power | 5.5-55 kW |

| Vibration Frequency | 700-1000 rpm |

| Screen Angle | 15°-30° adjustable |

Special Configurations Available:

- High-frequency screens(for particles <3mm)

- Banana screens (for sticky materials)

- Dewatering screens(up to 200 G-force)

Why Choose CATHAY?

✓ 25+ Years Manufacturing Experience

- 1500+ units installed worldwide

- ISO 9001:2015 certified production

✓ Custom Engineering Solutions

- Site-specific designs for unique material challenges

- 3D modeling and factory acceptance testing

✓ Global Support Network

- 12 regional service centers

- 48-hour emergency response

✓ Sustainable Design

- 30% less energy consumption vs conventional screens

- 95% recyclable materials

Industry Case Studies

Copper Mine in Chile

- Installed 12×3.6m double-deck screens

- Achieved 98.5% screening efficiency for -12mm ore

- Reduced maintenance downtime by 40%

Quarry Plant in Germany

- Custom banana screens for wet limestone

- Increased throughput by 35%

- Noise levels below 75 dB(A)

Table parameters

|

型号 Model

|

进料粒度(mm) Granularity

|

筛孔(mm) Sieve pore

|

产量(t/h) Capacity

|

频率(min-1 Frequency

|

)倾角(°) Dip

|

功率(Kw)

Power

|

外形尺寸(mm)

Dimension

|

重量(kg) Weight

|

|

YK0612

|

40

|

1-25

|

5-10

|

1000

|

15-25

|

0.55

|

1370×890×330

|

340

|

|

YK0918

|

40

|

1-25

|

15-20

|

1000

|

15-25

|

2.2

|

2150×1358×575

|

550

|

|

YK1225

|

100

|

5-40

|

20-50

|

850

|

15-20

|

5.5

|

2762×1714×680

|

1100

|

|

YK1530

|

100

|

5-60

|

60-150

|

800

|

15-25

|

7.5

|

3320×1449×787

|

2100

|

|

YK1545

|

400

|

6-80

|

100-200

|

800

|

15±2.5

|

11

|

4610×2466×2258

|

3600

|

|

YK1860

|

400

|

8-100

|

150-300

|

800

|

15±2.5

|

11

|

5900×2827×2299

|

5200

|

|

YK2160

|

400

|

10-120

|

150-400

|

800

|

20±2.5

|

15

|

5900×3096×2804

|

7400

|

|

2YK2160

|

400

|

15-200

|

200-500

|

800

|

15±2.5

|

22

|

5900×3527×2988

|

8000

|

|

2YK2460

|

400

|

15-200

|

300-600

|

800

|

20±2.5

|

30

|

7020×3140×1530

|

9000

|

|

3YK2460

|

400

|

15-200

|

300-700

|

800

|

20±2.5

|

37

|

7300×3140×1910

|

1100

|

|

2YK2770

|

400

|

15-300

|

400-800

|

750

|

20±2.5

|

22×2

|

7600×4320×1620

|

12000

|

|

3YK2770

|

400

|

15-300

|

500-900

|

750

|

20±2.5

|

22×2

|

7800×4320×2120

|

14000

|

|

2YK3075

|

400

|

15-400

|

600-1200

|

750

|

20±2.5

|

30×2

|

7600×4620×1620

|

16000

|

|

3YK3075

|

400

|

15-400

|

700-1600

|

750

|

20±2.5

|

30×2

|

7800×4620×2120

|

18000

|

|

2YK3680

|

400

|

15-500

|

800-1800

|

750

|

20±2.5

|

37×2

|

7600×5120×1620

|

20000

|

|

3YK3680

|

400

|

15-500

|

900-1900

|

750

|

20±2.5

|

37×2

|

7800×5120×2120

|

22000

|