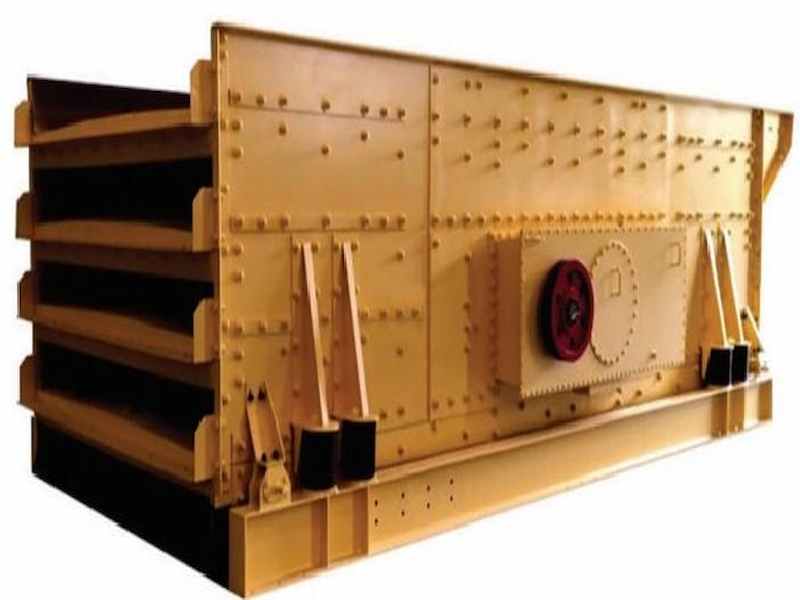

CATHAY linear vibrating screen adopts dual motor synchronous excitation technology and is designed for efficient grading and precise screening of materials such as ore, sand, gravel, coal, etc. The equipment has a processing capacity of 5-300 tons/hour and a screening accuracy of up to 0.074mm. It is an ideal choice for ore dressing plants, aggregate production lines and industrial powder processing.

Core advantages

1. Efficient screening performance

- Multi-layer classification: 1-5 layers of screen configuration, single machine realizes synchronous separation of multiple particle sizes

- Large processing capacity: optimize the screen surface inclination (15°-25°), and increase production capacity by 30%

- High precision: using polyurethane/metal composite screen plate, screening efficiency ≥92%

2. Super durable structure

- Box: Q345 steel plate integral welding, dynamic stress analysis optimization

- Screen: optional high manganese steel/rubber/stainless steel, life of 6-24 months

- Vibrator: SKF/FAG bearing, 50,000 hours maintenance-free design

3. Intelligent and stable operation

- Frequency conversion control: adjust amplitude (4-8mm) and vibration frequency (700-1000rpm)

- Overload protection: automatic shutdown + SMS alarm dual protection

- Internet of Things option: real-time monitoring of vibration parameters, temperature and output

4. Economic and environmentally friendly design

Reduced energy consumption: Optimized counterweight, 15-20% less electricity than traditional models

- Fully enclosed structure: dust spillage <10mg/m³**

- Quick-detachable screen frame: replacement time <30 minutes**

Technical parameters

| Parameters | Specification range |

| Model | ZKS/DZSF series |

| Screen surface size | 0.9-4.5m² (single layer) |

| Processing capacity | 5-300 t/h |

| Screening size | 0.074-50mm |

| Power | 2×0.75-2×22kW |

| Noise level | ≤75 dB(A) |

Industry solutions

✔ Metal mines: Iron ore/copper ore-3mm fine-grained grade efficient classification

✔ Sand and gravel aggregates: 0-5mm precise control of machine-made sand (including stone powder recovery system)

✔ Coal industry: 25-80mm particle size screening of raw coal (explosion-proof models are optional)

Table parameters

|

型号 Model

|

筛面面积(m²)

Area

|

振动频率(Hz) Frequency

|

功率(kw)

Power

|

双振幅(mm) 筛孔尺寸(mm) Amplitude Mesh size

|

处理能力(t/h) Capacity

|

安装倾角(°) tilt angle

|

|

GNLMZ1236

|

4.32

|

16

|

2×2.2

|

4~6

|

02-25mm

|

8~20

|

±4

|

|

GNLMZ1536

|

5.4

|

2×3

|

12~25

|

|

GNLMZ1836

|

6.48

|

2×5

|

24~32

|

|

GNLMZ1848

|

8.64

|

2×5

|

25~35

|

|

GNLMZ2448

|

11.52

|

2×7

|

30~45

|