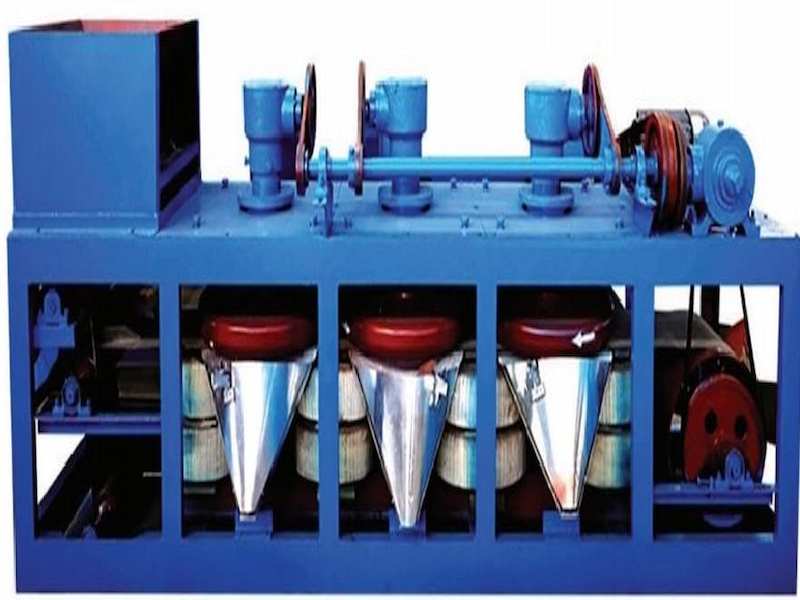

CATHAY three-disc belt magnetic separator: multi-disc coordinated high-efficiency magnetic mineral separation equipment

1. Three-disc coordination to enhance magnetic separation efficiency

CATHAY three-disc belt magnetic separator adopts a three-disc series structure, each disc is equipped with an independent strong magnetic system (magnetic field strength can reach 8000-15000 Gauss), and operates in linkage through a circular conveyor belt. When the slurry enters the magnetic separation area of the first disc, the strongly magnetic minerals are first adsorbed; the remaining slurry flows into the second disc, and the medium magnetic minerals are accurately captured; finally, the slurry entering the third disc is separated by the weak magnetic minerals under the action of the enhanced magnetic field. The three discs work together to form a gradient separation process, which is 40%-50% higher than the separation efficiency of a single-disc magnetic separator, and the total recovery rate of magnetic minerals can reach more than 95%.

2. Accurate classification, suitable for magnetic ores of various particle sizes

For magnetic minerals of different particle sizes (0.05-3mm), the three discs can set the magnetic field strength and belt speed (adjustable 0.5-2m/min) respectively: coarse-grained minerals (1-3mm) are quickly adsorbed by the strong magnetic field on the first disc to avoid missed selection due to large particles; medium-grained minerals (0.2-1mm) are separated at medium speed on the second disc to improve the sorting accuracy; fine-grained minerals (0.05-0.2mm) are transported slowly on the third disc to ensure full adsorption. The concentrate grade is 10%-15% higher than that of traditional equipment, meeting the production needs of different purity requirements.

3. Wide application, covering the sorting of multiple types of magnetic minerals

It can efficiently process magnetic minerals such as magnetite, pyrrhotite, hematite (after magnetization roasting), manganese ore, ilmenite, etc., and has outstanding performance in the fields of ferrous metal ore sorting, rare metal recovery, and non-metallic ore iron removal. Whether it is the roughing and concentrating links of the mine or the purification of raw materials in the metallurgical industry, it can play a stable role, especially suitable for processing mixed minerals with complex components and large magnetic differences.

4. Stable structure, durable and reliable magnetic separation system

The magnetic system adopts high-performance NdFeB permanent magnet material, with stable magnetic field strength, attenuation rate less than 3%/year, and service life of up to 8-10 years. The conveyor belt is made of wear-resistant rubber material, with a smooth surface and tear resistance. With precise tensioning device, it runs smoothly without deviation and has a service life of more than 3000 hours. The frame is welded with high-strength steel and treated with anti-corrosion to adapt to the humid and dusty mineral processing environment, ensuring the long-term stable operation of the equipment.

5. Intelligent operation and convenient parameter adjustment

Equipped with PLC control system, the three-disc magnetic field strength, belt speed, slurry flow and other parameters can be set through the touch screen, and one-button start and automatic shutdown functions are supported. The equipment has built-in multiple sorting modes, and preset parameters can be quickly called for different types of minerals to reduce debugging time. It is equipped with a real-time monitoring interface to display the operating status and sorting data of each disk, which is convenient for operators to make timely adjustments and reduce management difficulty.

6. Low consumption and high efficiency, economical operation cost

The design of independent drive of each disc is adopted, and the total power of the motor is only 2.2-4kW, which reduces energy consumption by 20%-25% compared with multi-disc equipment with the same processing capacity. The equipment has a compact structure and occupies a small area (about 3-5㎡), and does not require a complex foundation for installation. Daily maintenance mainly includes cleaning the magnetic separation surface and checking the tension of the conveyor belt. The maintenance cost is low, and the annual operating cost is only 2%-3% of the total price of the equipment.

7. Diverse specifications, customizable on demand

Two series of standard and enhanced types are provided, and the processing capacity of a single unit covers 1-20 tons/hour, which can be flexibly selected according to the scale and production capacity requirements of the mine. It supports the customization of parameters such as the magnetic field intensity range and the width of the conveyor belt according to the characteristics of the ore type to ensure that the equipment is perfectly adapted to the production process and meet the personalized sorting needs.

8. CATHAY brand guarantee, worry-free service throughout the process

Each three-disc belt magnetic separator undergoes strict magnetic performance testing and belt running tests before leaving the factory to ensure that the performance meets the standards. The professional after-sales team provides on-site installation and commissioning, operation training, regular inspections and other services. The 7×24-hour technical hotline responds to customer inquiries at any time and promptly solves problems in equipment operation. From equipment selection to post-maintenance, CATHAY escorts the entire process, allowing customers to produce with greater peace of mind.

Company Project

|

型号 Model

|

磁场强度(gs)

Magnetic field

intensity

|

磁盘转速 (r/min)

Disk speed

|

激磁线图

Magnetizi

ng coil

|

电机

(kw)

Motor

|

给料粒度(mn) Feed grain

size

|

外形尺寸(mm) Shape size

|

生产能力

(t/h)

Throughput

|

重量(t) Weight

|

|

CP3-500

|

17000

|

25-40

|

4

|

1.1

|

<2

|

2800×800×1220

|

0.1-0.5

|

1.9

|

|

CP3-600

|

18000

|

22-38

|

4

|

1.5

|

<2

|

3150×900×1250

|

0.15-0.8

|

2.2

|

|

CP3-500-1

|

20000

|

22-38

|

4

|

1.5

|

<2

|

3150×900×1250

|

0.1-0.8

|

2.3

|