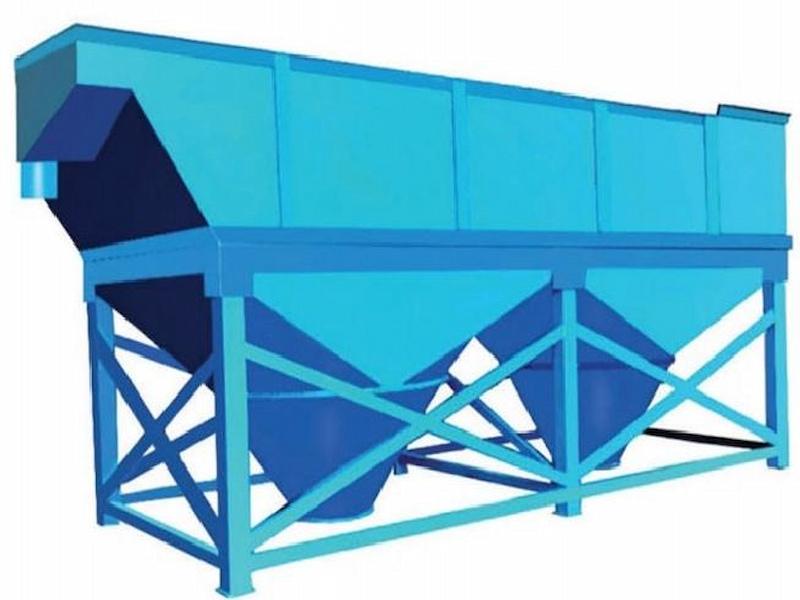

CATHAY oblique tube thickener: Oblique tube empowerment leads the new trend of efficient concentration

1. Oblique tube sedimentation innovation accelerates the solid-liquid separation process

CATHAY oblique tube thickener cleverly combines gravity sedimentation and oblique tube strengthening technology to break through the efficiency bottleneck of traditional thickeners. Hexagonal thin-walled porous oblique tubes are tightly arranged at a specific angle inside the equipment. When the slurry or liquid to be treated flows from the feed area into the sedimentation and concentration area, a relatively dynamic equilibrium suspension system is formed. At this time, particles with larger particle size overcome the pulsation force of water flow with a faster final sedimentation velocity, and quickly settle through the suspended filtration layer in the sedimentation and concentration area, and reach the bottom discharge port for discharge. Particles with smaller particle size that fail to settle in time flow into the oblique tube area with the rising water flow. The oblique tube area divides the water flow into many tiny sedimentation units. Under the conditions of laminar hydraulic sedimentation, fine particles quickly adhere to the wall of the oblique tube. After accumulating to a certain amount, they slide back to the sedimentation area under the traction of gravity. During the whole process, the inclined tube greatly expands the sedimentation area, greatly shortens the particle sedimentation path, and increases the sedimentation speed by 40%-60% compared with ordinary thickeners, significantly accelerating solid-liquid separation and greatly improving the concentration efficiency.

2. Multi-scenario adaptation to meet multiple concentration needs

In the field of metal ore beneficiation, whether it is the concentration of raw ores and concentrates such as gold, copper, and iron ore, or the tailings treatment link, CATHAY inclined tube thickener can show its prowess. Taking gold ore beneficiation as an example, the slurry can be efficiently concentrated to provide slurry of suitable concentration for subsequent processes such as cyanide leaching, thereby improving the leaching rate of gold; in the treatment of tailings, it can effectively reduce the water content of tailings, facilitate dry stacking or secondary utilization of tailings, and reduce the area occupied by tailings ponds and environmental pollution risks. In the processing of non-metallic minerals, the purification and concentration of slurries such as kaolin and quartz sand are also effective, which can remove impurities and improve product purity and quality. In addition, in the scenarios of sewage treatment and industrial slurry concentration in the chemical and environmental protection industries, the equipment can also achieve stable and efficient solid-liquid separation with its excellent performance, and its adaptability is extremely wide.

3. Efficient concentration results, significantly reducing the water content of the slurry

After being treated by the CATHAY inclined tube thickener, the water content of the slurry has been greatly reduced. For common metal ore slurries, if the initial feed moisture content is in the range of 60%-80%, after equipment concentration, the discharge moisture content can be stably reduced to 30%-40%. This outstanding achievement greatly reduces the workload of subsequent dehydration equipment (such as filter presses, dryers, etc.), improves the overall dehydration efficiency, and reduces energy consumption and operating costs. In addition, the concentration of the concentrated underflow slurry is uniform and stable, which lays a solid foundation for the subsequent continuous and stable production process, and effectively avoids the adverse effects of fluctuations in slurry concentration on the process.

4. Intelligent and precise control to ensure stable operation of equipment

CATHAY inclined tube thickener is equipped with an advanced PLC intelligent control system. Through a series of high-precision online monitoring equipment, such as concentration meters to control the changes in slurry concentration in real time, liquid level sensors to accurately monitor the liquid level, and flow sensors to stably adjust the slurry flow, the system collects equipment operation data in all directions and in real time. According to the preset program, the system automatically and accurately adjusts the amount of flocculant added to ensure that the agent and the slurry react fully and optimize the sedimentation effect; at the same time, it intelligently controls the stirring speed to maintain a reasonable suspension state of particles in the slurry to avoid uneven sedimentation; and automatically adjusts the mud discharge frequency according to the bottom flow concentration and liquid level to ensure that the equipment is always in the best operating state. Operators only need to use the visual display screen in the central control room to remotely and conveniently monitor the overall operation of the equipment, and make fine adjustments to the parameters in time, which greatly reduces manual intervention, reduces labor intensity, and significantly improves the accuracy and efficiency of production management.

5. Sturdy and durable structure to ensure long-term stable operation

The main body of the equipment is made of high-strength, corrosion-resistant high-quality steel. After special processing, a dense protective layer is formed on the surface, which can resist the erosion of various complex slurry components, including harsh environments such as high acid, alkali, and high salt, and the service life is more than 15 years. The internal inclined tube is made of food-grade, anti-aging, and wear-resistant polypropylene material. It has excellent chemical stability and mechanical strength, can withstand long-term water flow erosion and particle collision, and is not easy to deform or break, ensuring the long-term stable operation of the inclined tube structure and reducing the frequency of equipment maintenance and replacement. Key transmission components, such as motors and reducers, are all selected from internationally renowned brands, with excellent performance and stable operation. They are equipped with high-precision bearings and sealing devices to effectively reduce equipment operating noise and failure rate, ensuring that the equipment continues to operate stably under high-intensity working conditions.

6. Energy-saving and consumption-reducing design to help enterprises reduce costs and increase efficiency

During the design stage, the CATHAY R&D team has always adhered to the concept of energy saving. Through the optimization design of the overall structure of the equipment and the water flow path, the resistance of the slurry flowing inside the equipment is greatly reduced, reducing unnecessary energy loss. At the same time, the power of the mixing system and the mud discharge device is accurately matched, and high-efficiency and energy-saving motors are selected, which reduces energy consumption by 20%-30% compared with traditional thickeners. In addition, the equipment adopts a non-powered or micro-powered operation mode (depending on the model), which further reduces power consumption and reduces the company's operating costs, which is in line with the current industry development trend of green mines, energy conservation and environmental protection, and creates more economic and environmental benefits for the company.

7. Customized specification selection to fit the company's production scale

CATHAY fully considers the production scale and actual needs of different companies and provides a wide variety of inclined tube thickener specifications and models. The equipment diameter ranges from 5 meters to 50 meters, and the processing capacity covers 50-5000 tons/day. The most suitable equipment solution can be tailored for customers based on factors such as slurry output, concentration, and company site space. From early project planning, precise equipment selection, mid-term professional installation and commissioning, to later long-term technical support, CATHAY's professional team provides one-stop caring services to ensure that the equipment is seamlessly integrated into the company's existing production process and maximizes its efficiency.

8. CATHAY brand escort, worry-free after-sales guarantee

As a well-known brand in the field of solid-liquid separation equipment for many years, CATHAY has accumulated profound technical background and rich experience in the research and development and manufacturing of inclined tube thickeners. Before leaving the factory, each equipment must undergo strict quality inspection and performance testing, covering multi-dimensional inspection processes such as strength testing, sealing testing, and sedimentation efficiency testing to ensure excellent product quality and performance compliance. The professional after-sales team provides 24-hour technical consulting services all year round to answer customers' questions at any time; regularly arrange equipment inspections to promptly discover and solve potential problems; once the equipment fails, the after-sales staff will respond quickly and rush to the site for repairs as quickly as possible. The reserve of wearing parts is sufficient to ensure that the equipment can resume normal operation in the shortest time, so that customers can use the equipment without any worries. Choosing CATHAY inclined tube thickener means choosing an efficient, stable, energy-saving, and environmentally friendly slurry concentration solution. Join hands with CATHAY to embark on a new journey of efficient production and green development.

Table parameters

|

型号 Model

|

面积(m²)

Area

|

外形尺寸(mm)

Dimensions

|

蜂窝管径(mm) Caliber

|

反冲水压力(kg)

Pressure

|

矿浆浓缩(t/d) 水回收(t/d) Concentrate Water recovery

|

重量(t) Weight

|

|

TY-1

|

1

|

1700×1245×2610

|

35

|

>3

|

60-150

|

100-150

|

3.5

|

|

TY-5

|

5

|

3550×2446×3795

|

35

|

>3

|

300-800

|

500-1000

|

3.5

|

|

TY-10

|

10

|

7100×2446×3795

|

35

|

>3

|

500-1500

|

1000-1500

|

5.2

|