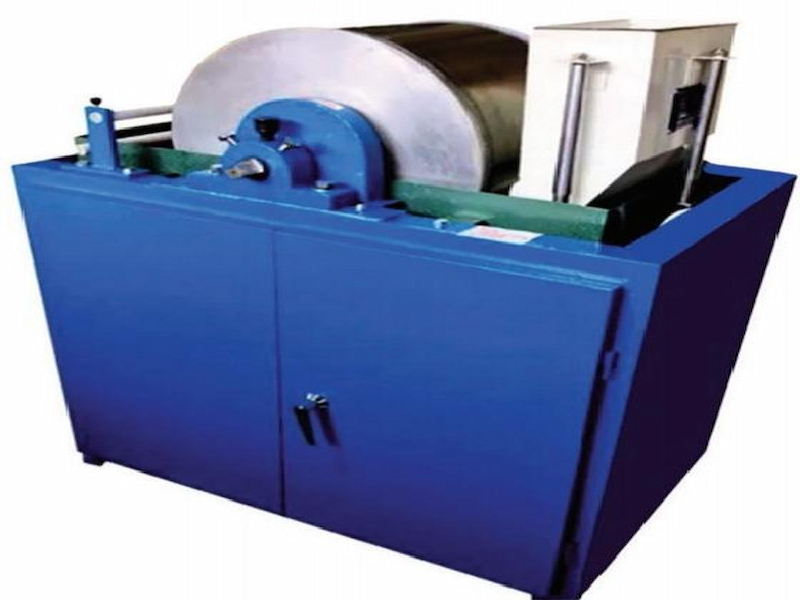

CATHAY experimental magnetic separator: magnetically driven, precise tool for laboratory magnetic mineral separation

1. Principle of magnetic separation to achieve efficient separation of magnetic minerals

CATHAY experimental magnetic separator uses the attraction of magnetic field to magnetic minerals to achieve separation of magnetic and non-magnetic minerals. The core of the equipment consists of a magnetic system (permanent magnet or electromagnetic), a separation device (drum, trough or belt), a feeding system and a discharge mechanism. When the ore pulp (concentration 10%-40%) or dry ore sample enters the separation area, the magnetic mineral particles are adsorbed on the surface of the separation device by the magnetic field, and fall off after the device moves to the non-magnetic area, becoming a magnetic product; non-magnetic mineral particles are not affected by the magnetic field force, and are directly discharged under the drive of gravity or water flow, becoming a non-magnetic product. By adjusting the magnetic field strength (0.1-2.0T continuously adjustable), the magnetic field gradient and the separation speed (0.5-5m/min), minerals with different magnetic strengths (such as strong magnetic magnetite and weak magnetic hematite) can be accurately separated, and the separation efficiency is more than 90%, providing reliable data for the study of the selectivity of magnetic minerals.

2. Multi-type adaptation, covering the needs of magnetic mineral experiments

Strong magnetic mineral separation: For strong magnetic minerals such as magnetite and pyrrhotite, efficient purification can be achieved. In the magnetite separation experiment, a magnetic field strength of 0.3-0.8T is used, and the magnetic iron ore particles are firmly adsorbed on the drum surface. Non-magnetic gangue (such as quartz and feldspar) are discharged with the slurry. The iron grade of the concentrate can be increased from 30% to more than 65%, and the iron grade of the tailings is reduced to less than 5%, which clearly reflects the magnetic separation recovery effect of magnetite and provides parameter reference for the design of industrial magnetic separation process.

Weak magnetic mineral separation: Suitable for the separation research of weak magnetic minerals such as hematite, limonite, and siderite. High gradient magnetic separation technology (magnetic field strength 1.0-2.0T) is used to enhance the magnetic field gradient through magnetic media (such as steel wool and grids) so that weak magnetic minerals can be effectively adsorbed. In the hematite sorting experiment, combined with magnetization roasting pretreatment (converting hematite into magnetite), the grade of magnetic separation concentrate can reach more than 55%, and the recovery rate is increased to 80%, providing experimental basis for the development and utilization of weakly magnetic minerals.

Rare metal ore impurity removal: used to remove magnetic impurities in ilmenite and zircon sand. In the ilmenite sorting experiment, the magnetic field strength is adjusted to 0.5-1.0T, and the magnetic gangue (such as magnetite and pyrrhotite) can be separated out, and the purity of ilmenite concentrate is increased to more than 90%, meeting the requirements of subsequent smelting for raw material purity; for magnetic impurities in zircon sand (such as ilmenite), the purity of zircon sand can reach 95% after magnetic separation, which improves the product value.

Non-metallic ore purification: For non-metallic ores such as quartz sand, feldspar, and kaolin, magnetic impurities (such as iron minerals and biotite) can be removed. In the quartz sand purification experiment, the magnetic field strength of 0.6-1.2T can effectively adsorb iron impurities, reducing the iron content of quartz sand from 0.1% to below 0.01%, meeting the raw material standards of photovoltaic glass and electronic grade quartz sand. The experimental data can directly guide the industrial purification process.

Magnetic material classification: used for classification and purification experiments of magnetic powders and magnetic alloys. In the sorting experiment of permanent magnetic materials (such as NdFeB), by adjusting the magnetic field strength and sorting speed, powder particles with different magnetic strengths can be separated to obtain products with uniform magnetic properties, providing homogeneous raw materials for magnetic material performance research.

3. Performance advantages to ensure accurate and reliable experimental data

Controllable magnetic field parameters: Using a precision magnetic control system, the magnetic field strength adjustment accuracy reaches ±0.02T, which can be displayed in real time on the digital display screen; the magnetic field is evenly distributed (the magnetic field deviation in the same sorting area is ≤5%), ensuring that the force on the ore sample is consistent; it supports two modes: constant magnetic field and alternating magnetic field. The alternating magnetic field frequency (adjustable from 5 to 50Hz) can study the impact of magnetic field changes on the sorting effect and meet the needs of diversified experiments.

High sorting efficiency: The sorting device adopts an optimized design - the drum surface linear speed of the drum magnetic separator is uniform (error ≤0.1m/min), ensuring stable adsorption of magnetic particles; the slurry flow of the slot magnetic separator is stable, reducing the entrainment of non-magnetic particles. The single batch processing capacity is 0.1-5kg, and the sorting time is short (10-30 minutes/batch), which is suitable for small batch multi-group comparative experiments. The recovery rate deviation of multiple experiments on the same ore sample is ≤4%.

Flexible and convenient operation: supports two sorting modes, dry and wet - the dry method is suitable for dry ore samples (particle size 0.1-5mm), and the wet method is suitable for slurry (particle size 0.074-2mm); the feeding amount is precisely controlled by a screw feeder or a peristaltic pump (accuracy ±5%), and the discharge port height is adjustable to meet different production requirements. Equipped with a touch screen control system, 10 groups of sorting parameter schemes can be preset (such as "magnetite sorting" and "hematite sorting"), and the experiment can be started with one-click call to reduce manual intervention.

Visual observation: The sorting area uses a transparent protective cover, which can intuitively observe the adsorption, movement and shedding process of magnetic particles, and facilitate the recording of sorting phenomena under different magnetic field strengths (such as adsorption speed and adsorption amount). Equipped with a high-definition camera interface, it can be connected to the device to shoot the sorting dynamics for experimental analysis or teaching demonstrations.

4. Structural design, taking into account both experimental adaptability and durability

Miniature multifunctional design: The equipment occupies an area of only 0.5-1.0㎡, which is suitable for compact laboratory space; the magnetic separator has various types (drum type, trough type, and flat plate type are optional) to meet different experimental scenarios - the drum type is suitable for continuous sorting, the trough type is suitable for batch experiments, and the flat plate type is suitable for dry static sorting. A single device can achieve a variety of magnetic field strength adjustments, without the need to replace the magnetic system, reducing the cost of experimental equipment investment.

The magnetic system is stable and durable: The permanent magnetic system uses high-performance neodymium iron boron materials, the magnetic field strength is long-term stable (annual attenuation rate ≤2%), and the service life is more than 10 years; the electromagnetic magnetic system uses high-quality silicon steel sheets and copper wire windings, and the cooling system (air cooling or water cooling) ensures that the magnetic field is stable during long-term work without overheating and attenuation.

Anti-corrosion and wear-resistant treatment: The parts in contact with the slurry (tank body, drum surface) are made of 316 stainless steel or polyurethane, which is resistant to acid and alkali corrosion (can withstand slurry with pH2-12); the drum surface is hardened (hardness above HRC55), which can withstand long-term friction of ore particles and extend service life.

Safety and environmental protection design: The electromagnetic magnetic system is equipped with overcurrent protection and overheating protection devices to prevent circuit failure; the permanent magnetic system is equipped with a safety shield to prevent strong magnetic fields from affecting experimental personnel or electronic equipment (such as watches and mobile phones); the slurry circulation system of wet sorting adopts a sealed design to reduce slurry overflow, and wastewater can be collected and treated, which meets the environmental protection requirements of the laboratory.

5. CATHAY brand guarantee, helping magnetic mineral research

Each experimental magnetic separator is tested by standard ore samples (such as GBW07223 magnetite standard material) before leaving the factory to ensure that the magnetic field strength accuracy and sorting effect meet the standards. The professional technical team provides customized services - magnetic field distribution measurement devices, automatic sampling systems, or special sorting devices (such as weak magnetic separation modules with low magnetic field gradients) can be installed according to experimental requirements; on-site installation and commissioning, operation training and experimental program guidance are provided to assist scientific researchers in establishing magnetic separation experimental methods. 7×24 hours after-sales hotline response, 2-year warranty for core components (magnetic system, control system), sufficient inventory of wearing parts (such as conveyor belts, seals), to ensure long-term stable operation of the equipment.

From university research laboratories to mining enterprise R&D centers, CATHAY experimental magnetic separators provide solid support for magnetic mineral sorting experiments with their precise magnetic field control, efficient sorting performance, and flexible operation methods, helping to explore the separation mechanism of magnetic minerals in depth, optimize magnetic separation processes, and promote the efficient use of magnetic mineral resources.

Table parameters

|

型号 Model

|

磁场强度(gs) Intensity

|

分选物料粒度(mm) Granularit

|

处理量(kg/h) Capacity

|

电机功率(kw)

Power

|

外型尺寸(mm) Shape size

|

重量(t) Weight

|

|

400×300

|

2000

|

2

|

20-60

|

0.37

|

830×520×1020

|

230

|