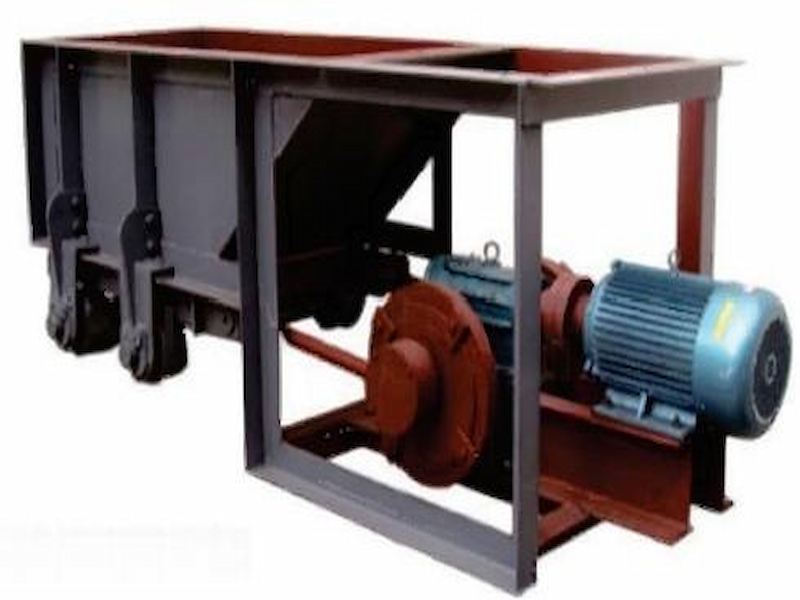

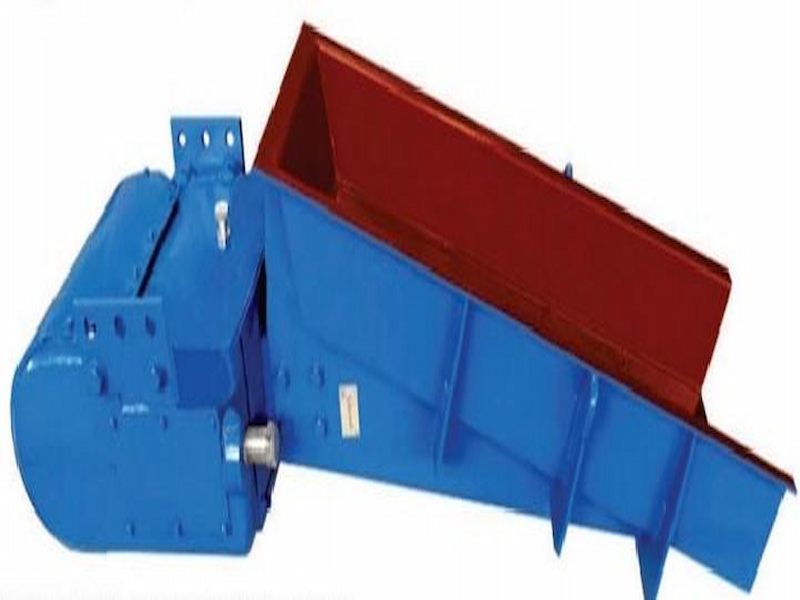

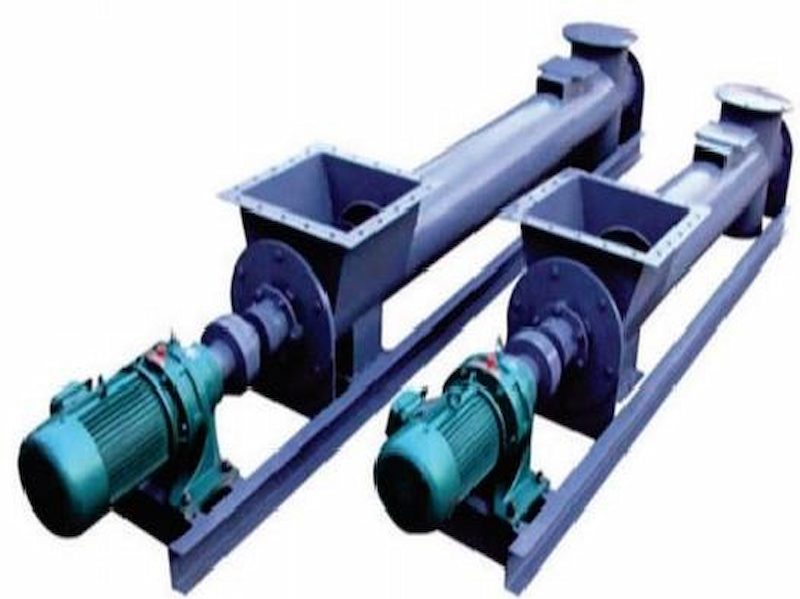

CATHAY belt feeder is a highly efficient continuous conveying equipment designed for mining, building materials, metallurgy and other industries. It adopts high-strength conveyor belt and modular structure to achieve large-capacity, uniform and stable transportation of block and granular materials. The equipment processing capacity can reach 50-2000t/h, meeting the diverse needs from small and medium-sized production lines to large mines.

Core advantages

1. Super durability

- Wear-resistant conveyor belt: EP/NN high-strength rubber belt**, with a 6-15mm wear-resistant layer on the surface, impact-resistant and tear-resistant, with a service life 50% longer than ordinary belts

- Heavy-duty structure: The grooved roller bracket adopts 10mm thick steel plate, with strong dynamic bearing capacity, suitable for harsh working conditions in mines

- Anti-deviation design: Equipped with automatic deviation correction device and anti-side roller to ensure long-term stable operation of the belt

2. Accurate and controllable

- Frequency conversion speed regulation: Siemens/ABB frequency converter is used, and the feed amount adjustment accuracy reaches ±2%

- Intelligent linkage: It can be connected to the PLC control system to achieve start and stop synchronization with the crusher and screening machine

- Multi-speed control: 5 speed modes are preset for different materials (such as ore and coal)

3. High efficiency and energy saving

- Low resistance design: Optimize the roller spacing (≤800mm), and reduce the operating power consumption by 15-20%

- Closed structure: Optional dust cover to reduce material spillage and meet environmental protection requirements

- Quick replacement: Modular design, belt replacement time ≤2 hours

4. Safe and reliable

- Double protection: Equipped with pull rope emergency stop switch + deviation alarm device

- Anti-slip treatment: The driving roller is wrapped with herringbone rubber, which does not slip in rainy days

- Anti-blocking design: Inverted V-shaped guide plate at the discharge port to prevent material jamming

Technical parameters

| Parameter item | Specification range |

| Band width | 500-2000mm |

| Belt speed | 0.1-2.5m/s adjustable |

| Conveying capacity | 50-2000t/h |

| Maximum inclination | ≤25° |

| Motor power | 5.5-160kW |

| Applicable materials | Ore, coal, sand and gravel, etc. (particle size ≤300mm) |

Industry solutions

✔ Metal mines: Used with jaw crushers to transport iron ore/copper ore (recommended bandwidth ≥1200mm)

✔ Sand and gravel aggregates: Used for feeding the secondary crushing buffer bin (dust-proof and sealed models are optional)

✔ Coal transfer: Cold-resistant belt model (applicable to low-temperature environments of -40℃)

✔ Cement production: High-temperature resistant design (material temperature ≤120℃)

Service Commitment

- 3-year warranty: Core components (drums, reducers) with extended warranty

- 48-hour response: 30 service outlets nationwide for quick on-site service

- Free design: Provide 3D layout plan + capacity estimation report

Table parameters

|

型号

Model

|

带宽(mm)

Belt width

|

首尾轮中心距(mm)

Center distance

|

首尾轮直径(mm)

Diameter

|

给料能(t/h)

Capacity

|

给料粒度(mm)

Feed grain size

|

功率(kw)

Power

|

重量(kg) Weight

|

|

500X1000

500X2000

|

500

|

1000

|

219

|

10-100

|

0-50

|

0.75

|

266

|

|

2000

|

20-100

|

0-50

|

2.2

|

609

|

|

500X3000

|

3000

|

30-100

|

0-50

|

2.2

|

697

|

|

500X4000

|

4000

|

40-100

|

0-50

|

2.2

|

736

|

|

650X1500

|

650

|

1500

|

50-100

|

0-50

|

2.2

|

610

|

|

650X2600

|

2600

|

60-100

|

0-50

|

2.2

|

636

|

|

650X4000

|

4000

|

70-100

|

0-50

|

2.2

|

893

|

|

800X2000

|

800

|

2000

|

80-150

|

0-80

|

2.2

|

721

|

|

800X3000

|

3000

|

90-150

|

0-80

|

7.5

|

857

|

|

800X4500

|

4500

|

400

|

100-150

|

0-80

|

2.2

|

1200

|

|

1000x2000

|

1000

|

2000

|

150-450

|

0-80

|

3

|

1549

|

|

1000X2500

|

2500

|

200-450

|

0-100

|

3

|

2105

|

|

1000X6000

|

6000

|

250-450

|

0-100

|

11

|

5214

|