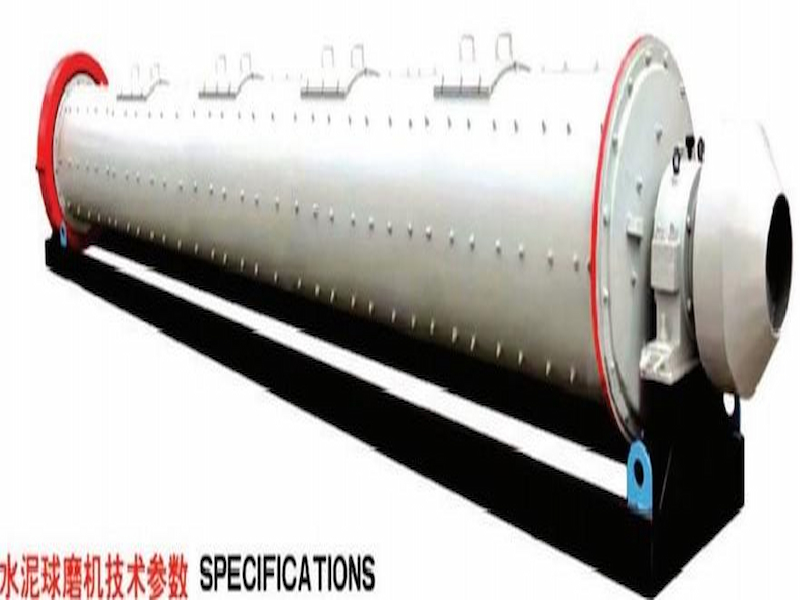

CATHAY ball mill, the core equipment for fine grinding of materials

1. Steel ball medium, strong grinding efficiency

Using high-strength wear-resistant steel balls as grinding media, the steel balls are driven to drop and roll with the help of the centrifugal force and friction generated by the rotation of the cylinder. The steel balls form a violent impact and continuous grinding on the materials in the cylinder, which can refine all kinds of ores and materials to the micron level, and grind thoroughly and evenly, meeting the strict requirements of high-precision processing on the fineness of materials, especially suitable for production links that require deep refinement.

2. Flexible adjustment to adapt to multiple needs

By adjusting the steel ball diameter ratio, cylinder speed and grinding time, the output particle size can be accurately controlled. Whether it is coarse grinding, fine grinding or ultra-fine grinding, it can be flexibly adapted. For materials with different hardness and humidity, such as metal ores, non-metallic ores, cement clinker, ceramic raw materials, etc., efficient grinding can be achieved, widely meeting the diversified needs of mining, building materials, metallurgy, chemical industry and other industries.

3. Stable structure and strong durability

The cylinder is welded with thick-walled high-quality steel, and the inner wall is lined with high manganese steel or rubber lining. It has excellent impact resistance and wear resistance, and can withstand long-term friction and impact between steel balls and materials. The steel balls are made of high-chromium alloy and are specially heat-treated. They have high hardness, are not easy to deform, and have a long service life, which greatly reduces the frequency of replacement of wearing parts and reduces maintenance costs.

4. Stable operation and convenient operation

Gear transmission or belt transmission system is adopted, and the power transmission is stable, with small vibration and low noise during operation. Equipped with an intelligent control system, it can monitor the grinding progress, equipment temperature and other parameters in real time, realize automatic start and stop, fault warning, and is simple and easy to operate. The equipment structure is reasonably designed, and the maintenance door is easy to open, which is convenient for daily maintenance and steel ball replenishment to ensure production continuity.

5. Wide application in various industries and high adaptability to scenarios

In metal mines, it is used for fine grinding before ore selection to improve efficiency for subsequent ore selection; in the building materials industry, it grinds cement raw materials and clinker to help produce high-quality cement; in the chemical industry, it grinds raw materials ultra-finely to meet the requirements of chemical reactions for material fineness. At the same time, it also plays an important role in the ceramic, glass, coating and other industries, becoming a key equipment for fine processing of materials.

6. Energy saving and environmental protection, green production assistance

The use of high-efficiency energy-saving motors reduces the unit grinding energy consumption compared to traditional equipment, and the operating cost is lower. The equipment has good sealing performance and is equipped with professional dust removal devices to effectively control dust spillage, reduce material loss and environmental pollution. The operating noise has been optimized to meet environmental protection standards, creating a clean and low-noise working environment for the workshop.

7. Brand guarantee, caring after-sales service

CATHAY ball mill integrates many years of experience in grinding equipment manufacturing. From raw material selection to finished product testing, every step is strictly controlled to ensure stable equipment performance and reliable quality. The professional after-sales team provides on-site installation and commissioning, technical training, regular inspections and other full-service, timely solve problems in equipment operation, so that production has no worries.

Table parameters

Table parameters

|

型号 Model

|

转速(r/min) Speed

|

装球量(t) Ball weigh

|

给料粒度(mm) Granularity

|

产量(t/h) Capacity

|

功率(kw)

Power

|

外形尺寸(mm) Shape size

|

重量(kg) Weight

|

|

GZM0924

|

39.3

|

1.9

|

0~15

|

0.5-2

|

15

|

4140×1920×1270

|

5666

|

|

GZM1224

|

35.1

|

4

|

0-25

|

1.6-5

|

37

|

5540×2300×1850

|

10020

|

|

GZM1530

|

30.7

|

7.3

|

0-25

|

6-12

|

75

|

7430×2930×2060

|

16843

|

|

GZM1836

|

25.04

|

23.2

|

0-25

|

7-21

|

155

|

9825×3960×2250

|

31440

|

|

GZM2145

|

23.8

|

21.4

|

0-25

|

25-42

|

245

|

9975×4060×3400

|

49230

|

|

GZM2464

|

23

|

36.7

|

0-25

|

40-100

|

475

|

12470×5000×3970

|

86180

|

|

GZM2742

|

21.7

|

33.1

|

0-25

|

55-135

|

570

|

11175×5610×4500

|

90420

|

|

GZM3036

|

19.5

|

32.8

|

0-25

|

80-150

|

570

|

14725×6730×5400

|

102000

|

|

GZM3245

|

18.7

|

49

|

0-25

|

160-245

|

630

|

13000×7200×5700

|

145000

|