Tel : 0663568213 Email : zhikangxie1@gamil.com

What Are You Looking For?

Popular Searches :

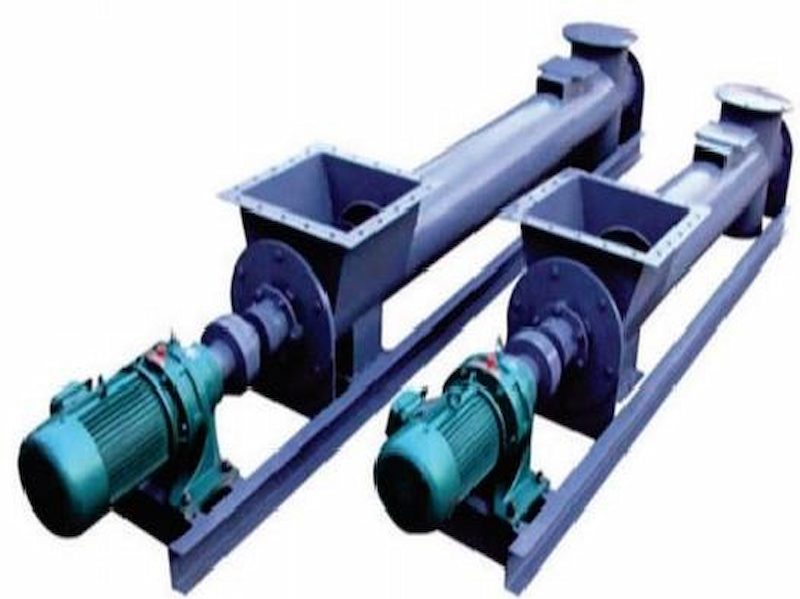

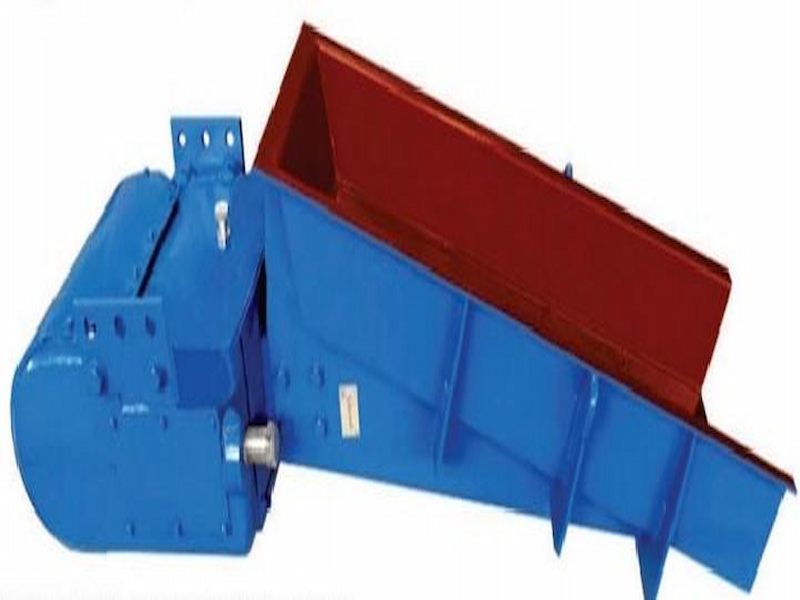

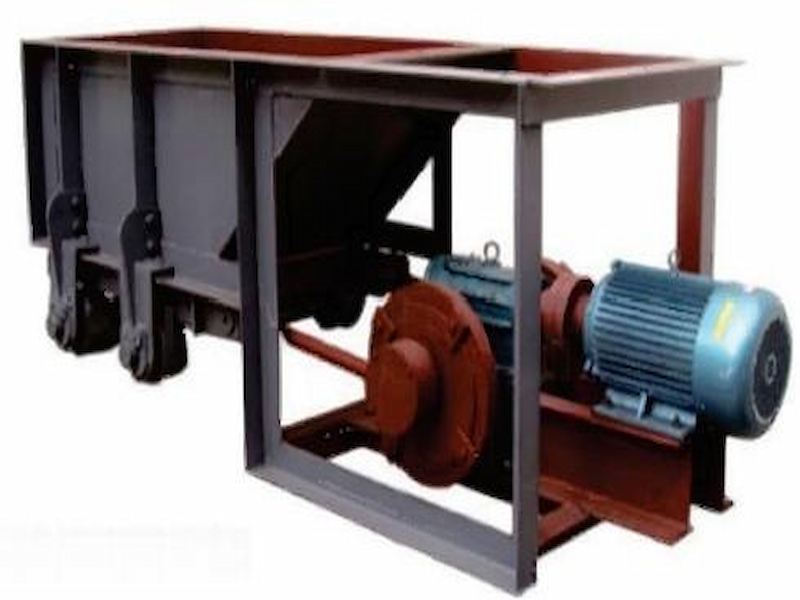

Trough Feeder Swing feeder Disc feeder Vibrating feeder Electromagnetic vibrating feeder Screw FeederWhat Are You Looking For?

Popular Searches :

Trough Feeder Swing feeder Disc feeder Vibrating feeder Electromagnetic vibrating feeder Screw Feeder